When hail the size of golf balls strikes your Denver commercial building, does your roof hold strong or leak into tenant spaces? The answer depends on which commercial roof type protects your property. Denver’s intense hail storms, high-altitude UV exposure, heavy snow loads, and freeze-thaw cycles demand careful selection of commercial roofing systems – systems that work in mild climates often fail prematurely here.

This guide breaks down major commercial roof types for Colorado property owners: TPO, EPDM, PVC, built-up roofing, modified bitumen, metal systems, and protective coatings. You’ll learn which systems perform best under Front Range weather, when repair makes sense versus replacement, and how to protect your investment through proper maintenance.

At Alliance Empire Development Solutions (Alliance EDS), we’ve spent over 15 years helping Denver property managers navigate these decisions with honest guidance, not high-pressure sales tactics. Let’s explore your options.

Why commercial roof type matters more in Denver

Your commercial roof faces challenges in Colorado that buildings in most other states never encounter. At Denver’s mile-high elevation, UV radiation is significantly more intense, breaking down roofing materials faster than at sea level. Large daily temperature swings cause constant expansion and contraction at seams and flashings. And unlike predictable coastal climates, the Front Range delivers extreme weather events with little warning.

The basic categories of commercial roof types include single-ply membrane systems, built-up and modified bitumen layers, metal panel roofs, and protective coating systems. Each responds differently to Denver’s climate stressors. A TPO roof that performs beautifully in Florida might fail prematurely in Colorado without proper thickness and installation details. Understanding these differences protects your property value and prevents expensive surprises.

Key weather challenges along the Front Range

Denver commercial roofs must withstand multiple severe weather patterns throughout the year:

- Hail storms: Colorado sits in “hail alley,” experiencing some of the nation’s most frequent and severe hail events. Large hailstones can puncture membranes, crack flashings, and dent metal panels.

- Freeze-thaw cycles: Water infiltrating small cracks or open seams expands when frozen, widening damage with each cycle and creating bigger leaks over time.

- Ponding water: Flat and low-slope roofs that don’t drain properly allow standing water to pool, accelerating membrane degradation and freeze damage.

- High winds: Taller buildings in downtown Denver or the Denver Tech Center face significant wind uplift forces that can tear poorly attached roofing systems.

- Heavy spring snow: Late-season snowstorms deposit wet, heavy snow that strains structural capacity and overwhelms inadequate drainage systems.

Professional-level concerns in this climate go beyond basic waterproofing. Proper drainage design, impact-resistant materials, carefully detailed seams and penetrations, and regular inspection of vulnerable points become essential maintenance tasks rather than optional upgrades.

Overview of main commercial roof types

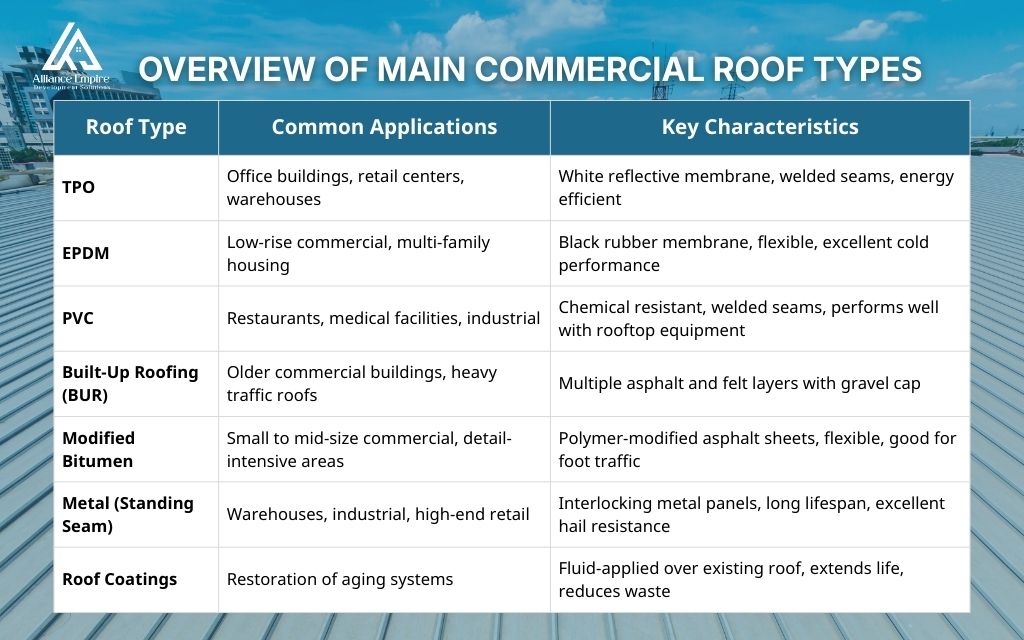

Before diving into specifics, here’s a quick comparison of the different types of commercial roofs you’ll find on Denver properties:

| Roof Type | Common Applications | Key Characteristics |

| TPO | Office buildings, retail centers, warehouses | White reflective membrane, welded seams, energy efficient |

| EPDM | Low-rise commercial, multi-family housing | Black rubber membrane, flexible, excellent cold performance |

| PVC | Restaurants, medical facilities, industrial | Chemical resistant, welded seams, performs well with rooftop equipment |

| Built-Up Roofing (BUR) | Older commercial buildings, heavy traffic roofs | Multiple asphalt and felt layers with gravel cap |

| Modified Bitumen | Small to mid-size commercial, detail-intensive areas | Polymer-modified asphalt sheets, flexible, good for foot traffic |

| Metal (Standing Seam) | Warehouses, industrial, high-end retail | Interlocking metal panels, long lifespan, excellent hail resistance |

| Roof Coatings | Restoration of aging systems | Fluid-applied over existing roof, extends life, reduces waste |

These types of commercial building roofs appear throughout Denver neighborhoods. In areas like LoDo, you’ll see mostly single-ply systems on modern mixed-use developments. RiNo warehouses often feature standing seam metal. Older buildings along Federal Boulevard may still have built-up roofs installed decades ago.

The right choice for your property depends on your building’s slope, existing deck and insulation, occupant needs, budget, and how long you plan to own the property.

Single-ply roofing systems (TPO, EPDM, PVC)

Single-ply membranes have become the most popular commercial roofing types in Denver. These systems provide a continuous waterproof layer installed in large sheets, minimizing seams where leaks typically start. They can be mechanically fastened, fully adhered, or ballasted depending on wind exposure and building requirements.

TPO roofs: Popular, reflective, and energy efficient

Thermoplastic Polyolefin (TPO) is the most widely installed single-ply membrane on Denver commercial flat roofs. This white or light gray membrane reflects solar heat, reducing cooling costs. Heat-welded seams create strong bonds that resist Denver’s wind and temperature extremes.

For Colorado applications, Denver roofers recommend 60-mil or thicker membranes with protective cover boards (versus standard 45-mil) to improve hail impact resistance and puncture protection around rooftop equipment. TPO’s reflective surface addresses Denver’s intense high-altitude UV exposure, but professional inspection after hail storms remains essential to catch small punctures before they cause insulation damage.

EPDM roofs: Flexible rubber for harsh conditions

EPDM rubber roofing has protected Denver commercial buildings for decades. This durable black membrane excels in cold temperatures, remaining flexible during freeze-thaw cycles that crack less adaptable materials. The membrane moves with thermal expansion and contraction rather than fighting it, reducing stress at seams and penetrations.

The darker surface absorbs more heat than white TPO, slightly increasing summer cooling costs. However, this proves advantageous in cold storage facilities or where snow melt is beneficial. Property managers choose EPDM for its proven track record and straightforward repairs. Regular inspections of seams, flashings, and penetrations remain critical.

PVC roofs: Chemical and grease resistant

PVC roofing systems offer specialized advantages for Denver commercial applications. Like TPO, PVC features hot-air welded seams, but distinguishes itself through chemical and grease resistance (ideal for restaurants, medical facilities, and industrial buildings)

PVC’s strong seam strength and flexibility around detail work prove valuable on roofs with numerous penetrations or heavy rooftop equipment. The membrane performs well in Denver’s climate when properly installed, though cold-weather installation requires experienced crews. Denver facilities like restaurants in the Denver Tech Center often select PVC for these specialized performance characteristics.

Built-up roofing (BUR) and modified bitumen

These traditional systems use multiple layers of asphalt and reinforcing materials to create redundant waterproofing. While newer single-ply membranes dominate the market, built-up and modified systems still serve important roles on Denver commercial roofs.

Built-up roofs: Layered protection for flat roofs

Built-up roofing (BUR) consists of alternating layers of bitumen (asphalt or coal tar) and reinforcing felts, topped with gravel, mineral granules, or a cap sheet. This multi-layer approach creates redundancy – even if the top layer sustains damage, additional layers beneath continue protecting your building.

Older Denver commercial properties, particularly along Federal Boulevard and Colfax Avenue, often feature BUR systems installed 20 to 40 years ago. These roofs handle significant foot traffic, making them suitable for buildings with frequent rooftop maintenance needs.

Denver climate challenges for BUR:

- Weight: Multiple layers create substantial roof load requiring adequate structural support

- Ponding vulnerability: Standing water can work between layers, causing blistering and accelerated deterioration

- Freeze-thaw damage: Trapped moisture expands when frozen, potentially separating the plies

Without regular professional inspections, Denver’s freeze-thaw cycles can significantly shorten BUR lifespan. Protective roof coatings applied over aging BUR systems sometimes extend service life by sealing the surface and improving water shedding.

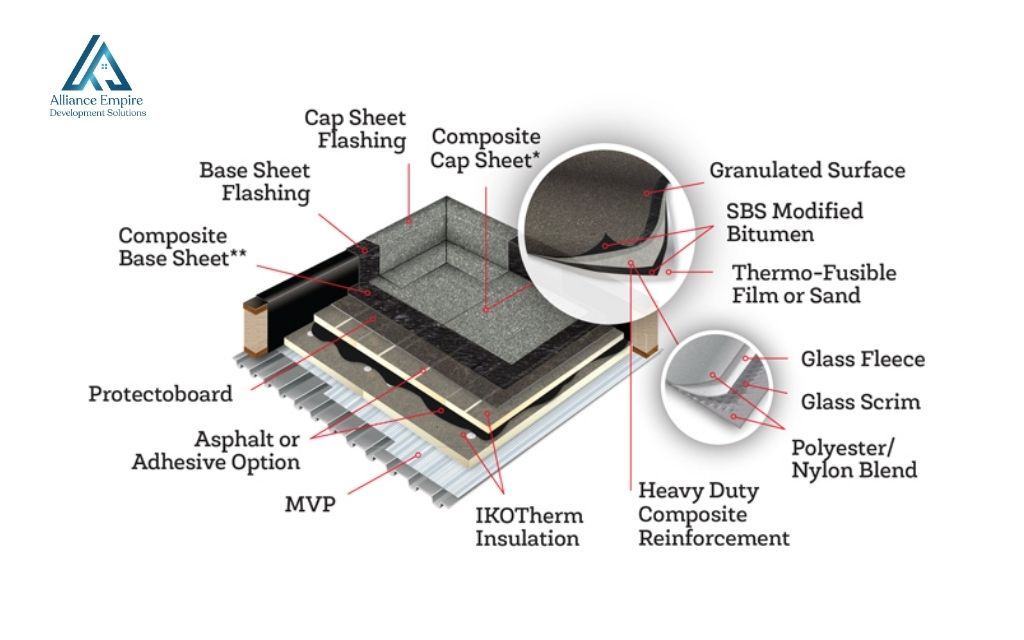

Modified bitumen: Modern upgrade for flat roofs

Modified bitumen represents an evolution of traditional built-up roofing. These asphalt sheets are modified with polymers (APP or SBS) that improve flexibility, elongation, and temperature performance. Installation methods include torch-applied, cold adhesive, or self-adhesive sheets.

Polymer modification provides strength against foot traffic while maintaining flexibility in cold temperatures. Many accept reflective cap sheets or protective coatings that address UV exposure concerns. Modified bitumen works particularly well on smaller Denver commercial roofs or transition areas where detail work around penetrations and edges requires careful attention.

Local roofers often recommend modified bitumen for properties wanting proven asphalt-based performance with better cold-weather characteristics than traditional BUR. The system bridges the gap between old-school built-up roofs and modern single-ply membranes.

Metal roofing systems for commercial buildings

Metal roofing brings exceptional durability and longevity to Denver commercial applications. Commercial metal systems protect warehouses, retail centers, industrial buildings, and multi-family properties throughout the metro area.

Standing seam metal roofs

Standing seam metal features interlocking panels with raised seams running vertically along the roof slope. Fasteners are concealed beneath seams rather than exposed to weather, reducing leak points. Common materials include steel, aluminum, and zinc with various coating systems.

Key performance factors for Denver:

- Wind uplift ratings: Panels must resist high winds, especially on taller structures

- Thermal movement: Metal expands and contracts significantly with temperature changes, requiring fastening systems that allow movement while maintaining waterproofing

- Underlayment quality: High-quality underlayment provides backup waterproofing

Metal performs exceptionally well under Denver hail and heavy snow loads. The material won’t rot, supports significant weight, and sheds snow readily. Hail may create cosmetic denting, though functional damage is rare unless hail is extraordinarily large. Insurance companies may treat cosmetic versus functional damage differently when processing claims.

Metal roofs on high-rise and taller buildings

For downtown Denver office towers or Denver Tech Center mid-rise buildings, metal roofing at higher elevations requires additional considerations. Wind uplift forces increase with height, making proper edge metal design, parapet details, and secure panel attachment even more critical.

These specialized applications require commercial roofing crews with high-rise experience, not general residential roofers. Fall protection, crane access, and coordination with occupied buildings demand different expertise than typical warehouse roofing projects.

Roof coatings and restoration systems

Rather than complete tear-off and replacement, roof coating systems can sometimes restore aging commercial roofs while extending service life. These fluid-applied systems create a new protective layer over existing membranes, metal, or built-up roofs.

Silicone, acrylic, and elastomeric coatings

Different coating chemistries serve different purposes:

- Silicone coatings: Excel at ponding water resistance and UV reflection, popular for flat Denver roofs with drainage challenges

- Acrylic coatings: Provide good UV protection and reflectivity but perform better on roofs with proper drainage

- Elastomeric coatings: Offer flexibility and elongation, helpful for roofs with thermal movement

Professional eligibility assessment includes:

- Substrate inspection: Is the existing roof membrane sound, or has it deteriorated too far?

- Moisture testing: Trapped moisture within roof layers will continue causing problems under a coating

- Adhesion testing: Will the coating chemistry bond properly to the existing surface?

- Surface preparation: Proper cleaning and priming ensure coating performance

When conditions allow coating restoration, property owners avoid complete tear-off waste, reduce project cost, and minimize tenant disruption. For Denver commercial buildings, silicone coatings offer particular value by addressing UV exposure and ponding water concerns simultaneously. However, coating a roof doesn’t eliminate the need for proper maintenance and professional inspections.

Choosing the best commercial roofing for your Denver building

With multiple types of commercial roofs available, selecting the right system requires evaluating factors beyond initial cost.

Factors to compare beyond just price

Expected lifespan in Denver climate

| System Type | Typical Denver Lifespan | Climate Vulnerabilities |

| TPO | 15-25 years | Hail puncture, seam failure |

| EPDM | 20-30 years | Seam adhesion, UV exposure |

| PVC | 20-30 years | Cold installation issues |

| BUR | 15-25 years | Freeze-thaw, ponding water |

| Modified Bitumen | 15-20 years | UV exposure, seam integrity |

| Standing Seam Metal | 30-50+ years | Fastener failure, coating breakdown |

| Silicone Coating | 10-20 years | Application quality, substrate condition |

Impact resistance and hail protection

Thicker membranes, protective cover boards, Class 4 impact-rated materials, and metal systems reduce hail damage risk. Some Colorado insurance carriers offer premium discounts for impact-resistant roofing, potentially offsetting higher initial costs.

Energy efficiency and operating costs

Reflective white roofs reduce cooling loads for air-conditioned buildings. Dark EPDM absorbs heat, which may increase summer costs but aids snow melt. Cool roof technologies can qualify for utility rebates through programs like Xcel Energy’s incentives.

Maintenance and disruption

Single-ply systems need seam inspections, metal roofs require panel attachment checks, and BUR systems benefit from periodic recoating. Consider installation odors, noise levels, and scheduling around business peaks when selecting materials.

Repair vs replacement: How to decide

Repair may work when:

- Damage is localized, not widespread

- Roof is less than halfway through expected lifespan

- Most membrane, seams, and flashings remain sound

- No trapped moisture or insulation saturation exists

- Repairs won’t void manufacturer warranties

Replacement makes sense when:

- Widespread membrane damage affects multiple areas

- Roof has reached or exceeded typical service life

- Moisture surveys reveal significant saturation

- Repeated repairs needed in different locations

- Energy costs increased due to deteriorated insulation

- Building sale or refinancing requires documented warranty

Professional tools like infrared moisture surveys and roof core samples provide objective data beyond visual inspection. Major manufacturers like Carlisle, Johns Manville, Versico, and GAF offer material and labor warranties that protect your investment—comprehensive coverage patchwork repairs can’t provide.

Why emergency issues need a professional, not DIY

When water pours through your ceiling, DIY patching creates serious risks:

- Safety: Wet membranes are slippery, ice makes roofs treacherous, and fall hazards abound. Professional roofers carry proper insurance and fall protection equipment.

- Warranty violations: Unauthorized repairs with incorrect materials or improper techniques can void manufacturer warranties.

- Insurance complications: Hasty DIY fixes hide original storm damage, reducing insurance settlements or creating disputes about pre-existing conditions.

- Hidden problems: Professionals use moisture meters, thermal imaging, and core sampling to identify trapped water and saturated insulation that visual inspection misses.

Alliance EDS provides emergency tarping and temporary waterproofing that stops immediate damage while preserving your options for thorough assessment and insurance support.

Denver-specific concerns: Hail, snow, and UV

Hail-resistant roof options

Denver sits in hail alley. Impact-resistant features include:

- Thicker membranes (60-mil or 80-mil TPO/EPDM vs. standard 45-mil)

- Protective cover boards beneath membranes

- Class 4 impact-rated systems (UL 2218 certified)

- Standing seam metal (resists functional damage)

- Reinforced flashings at penetrations and edges

Colorado insurance carriers may offer premium discounts for Class 4 systems, offsetting higher initial costs. Alliance EDS helps document damage properly after storms, differentiating cosmetic marks from functional failures for insurance claims.

Snow loads and freeze-thaw damage

Denver commercial roofs must handle snow weight and ensure proper drainage during melting:

- Structural capacity: Verify your building supports maximum expected snow loads

- Drainage adequacy: Blocked drains or poor design causes ponding that damages membranes

- Ice dams: Ice can block drainage and back water under roofing

- Freeze-thaw cycling: Water infiltrating cracks expands when frozen, widening damage

Flat and low-slope roofs require twice-yearly professional inspections minimum, plus additional checks after major storms. Spring inspections catch membrane splits and blocked drains before summer. Fall inspections prepare for winter.

High-altitude UV and energy efficiency

Denver’s mile-high elevation delivers intense UV radiation that breaks down roofing materials faster than sea-level locations.

UV protection strategies:

- Reflective roof systems (white TPO, PVC, coated metal)

- UV-resistant protective coatings on aging roofs

- Premium membrane formulations with enhanced UV stabilizers

- Periodic recoating to refresh UV protection

Reflective commercial roofing types reduce cooling loads and energy bills for air-conditioned buildings. Cool roof technologies may qualify for Xcel Energy utility rebates.

The combination of intense UV, temperature swings, hail risk, and snow loads makes Denver one of the country’s most challenging roofing climates. Investing in quality materials and professional installation pays dividends in longevity and reduced maintenance costs.

Professional inspections and maintenance plans

Even the best commercial roofing systems require ongoing professional attention to reach their expected lifespan. In Denver’s aggressive climate, maintenance isn’t optional.

Why regular commercial roof inspections matter

Professional roof inspections should occur at least twice per year, typically in spring and fall. Additional inspections after major hail storms, high wind events, or heavy snow help catch damage before small problems become emergency leaks.

What professionals check during inspections:

- Membrane condition across the entire roof surface

- Seam integrity and any signs of separation or weakening

- Flashing details around penetrations, skylights, edges, and drains

- Penetration seals at rooftop HVAC units, vents, and equipment

- Drain screens, scuppers, and gutters for blockages

- Ponding water areas indicating inadequate drainage

- Interior ceiling inspection for any evidence of leaks or moisture

- Documentation through photos and detailed reports

This systematic approach identifies developing issues while they’re still minor and affordable to fix. A small seam separation caught during inspection might cost a few hundred dollars to repair. That same separation ignored for another year could allow water infiltration that damages insulation and decking, turning a simple repair into a multi-thousand dollar project.

Denver roofs face more stress events than commercial buildings in most markets. Hail, wind, temperature extremes, snow, and UV exposure all accelerate aging. The frequency of severe weather makes proactive inspection even more valuable here than in stable climates.

Partnering with a Denver storm damage expert

Many roofing companies operate in the Denver metro area, but experience with Colorado’s specific climate challenges varies widely. Storm chasers flood into town after major hail events, make big promises, collect deposits, and disappear. Established local companies understand long-term performance, not just quick repairs.

Alliance Empire Development Solutions has served Denver and the surrounding Front Range communities for over 15 years. Our team combines:

- Storm damage expertise: We understand hail documentation, wind damage assessment, and insurance claim support specific to Colorado weather events

- Honest guidance philosophy: We explain when repair makes sense versus when replacement protects your investment better, even if repair is less profitable for us

- Local knowledge: Familiarity with Denver building codes, permit requirements, and inspection processes

- Comprehensive service: From emergency tarping through final installation and warranty support

This local, long-term approach contrasts sharply with out-of-state contractors who may not understand Colorado requirements or be available when warranty issues arise years later.

When storm damage strikes your commercial property, fast professional response prevents additional water damage to building contents and tenant spaces. But speed doesn’t mean cutting corners on assessment and documentation. Alliance EDS balances urgency with thoroughness, protecting both your building and your insurance claim.

FAQs about Denver commercial roof types

What is the best commercial roofing material for Denver’s hail and snow?

Thicker TPO (60-mil or 80-mil) with cover boards, flexible EPDM rubber, and standing seam metal all perform well against Denver’s hail and snow. Class 4 impact-rated systems offer additional protection and potential insurance discounts. Alliance EDS can assess your building and recommend the right system based on your slope, budget, and specific vulnerabilities.

How long do commercial TPO and EPDM roofs last in Denver’s climate?

Quality TPO typically lasts 15 to 25 years in Denver, while EPDM can reach 20 to 30 years with proper maintenance. Actual lifespan depends on installation quality, membrane thickness, and regular professional inspections. Denver’s aggressive weather accelerates aging, making expert installation and ongoing maintenance critical for reaching expected service life.

Is it better to repair or replace a leaking flat roof on my Denver building?

If your roof is less than halfway through its lifespan and damage is localized, repair often makes sense. However, widespread damage, saturated insulation, or a roof near its life expectancy points toward replacement. Alliance EDS conducts thorough inspections with moisture testing to give you honest, objective guidance on the best path forward for your investment.

How much does a new commercial roof cost per square foot in Denver?

Costs vary significantly based on system type, building size, removal needs, and detail complexity. Single-ply systems generally cost less than PVC or metal, but your specific project has unique factors. Contact Alliance EDS at (720) 207-4646 for a Virtual Roof Estimate or on-site assessment that provides accurate pricing for your actual building, not generic estimates.

Will my insurance cover hail damage to my commercial roof in Colorado?

Most commercial policies cover storm damage including hail, though coverage depends on your policy terms and proper damage documentation. Alliance EDS has extensive experience working with insurance adjusters on Denver claims, helping document damage properly and providing the technical information needed to maximize legitimate coverage for storm-damaged roofs.

Why choose Alliance Empire Development Solutions

When your Denver commercial building needs roofing service, you have many contractors to choose from. Alliance EDS stands apart through our commitment to honest guidance and long-term partnership with property owners.

5 reasons to choose Alliance Empire Development Solutions

- 15+ years serving Denver and the Front Range: We’ve weathered every hail storm, snowstorm, and weather extreme Denver throws at commercial roofs. This experience informs better recommendations and more reliable installations than contractors new to Colorado’s challenges.

- Honest guidance over aggressive sales: We tell you when repair makes sense instead of automatically pushing replacement. Our goal is your success and trust, not maximizing every invoice. Many clients call us specifically because they want straight answers, not high-pressure tactics.

- True local expertise in Denver’s climate: We understand how altitude affects UV aging, how Front Range freeze-thaw cycles damage flashings, and how Denver’s hail patterns create vulnerability. This isn’t generic roofing knowledge but specific Colorado experience that protects your investment.

- Storm damage specialists for insurance support: Hail, wind, and severe weather are our specialty. We document damage properly, work with insurance adjusters throughout the claim process, and ensure you receive fair consideration for legitimate storm damage. Our documentation has helped property owners secure coverage others were denied.

- Virtual Roof Estimate capability: Get your project started without waiting weeks for scheduling. Our Virtual Roof Estimate system provides preliminary assessment remotely, followed by detailed on-site inspection when needed. This speeds your timeline without sacrificing thoroughness.

Alliance Empire Development Solutions (Alliance EDS)

- Address: 1427 S Federal Blvd, Denver CO 80219

- Phone: (720) 207-4646 (Call Us – Available for Emergency Repair)

- Email: [email protected]

- Website: allianceeds.com

Contact us today for a thorough roof inspection, honest assessment of your commercial roofing system, or emergency storm damage response. We serve Denver, Lakewood, Aurora, Englewood, Littleton, Westminster, Arvada, Thornton, and surrounding Colorado communities with the same commitment to quality and integrity that has defined our work for over 15 years.

Conclusion

Choosing the right commercial roof type requires balancing performance, cost, and longevity for Denver’s extreme climate. Hail storms, intense UV, heavy snow, and freeze-thaw cycles make this decision critical – the wrong system can cost thousands in premature replacement and emergency repairs.

TPO, EPDM, and PVC membranes offer proven performance when properly specified. Built-up roofing and modified bitumen serve specific applications. Metal roofing provides exceptional durability. Roof coatings can extend life when restoration is viable.

With our professional installation, regular inspections, and proactive maintenance determine whether your roof reaches its expected lifespan or fails prematurely. Partnering with an experienced Denver roofing company protects your property value and prevents costly surprises.

Don’t wait for the next hail storm to reveal problems. Schedule a professional inspection now while issues are still manageable and affordable to address.